ug-84 impact test|heat impact test specimen : manufacturing Is it required that the material I use for the procedure qualification be impact tested? Material used in production would be impact tested, but I am wondering if my PQR . webChega de esperar dias pela correção da sua redação — a Glau entrega-lhe uma correção de qualidade em poucos segundos, gratuitamente! Comece agora. é grátis

{plog:ftitle_list}

WEBEndemol Shine Gaming, part of global content creator, producer and distributor Endemol Shine Group, and Pragmatic Play, a leading multi-product content provider for the .

For steel vessels of welded construction, the impact toughness of welds and heat-affected zones of procedure qua-lification test plates and vessel test plates (production impact test plates) shall be determined as required in this paragraph. Is it required that the material I use for the procedure qualification be impact tested? Material used in production would be impact tested, but I am wondering if my PQR . Do you have to do Production Weld impact test if you: A)Have ordered your material already impact tested (yes it is required to meet the MDMT) B)Have qualified Section .above, impact tests of welds and heat-affected zones shall be made in accordance with (g) above for each qualified welding procedure used on each vessel or group of ves-sels as .

Is lateral expansion the only acceptance criteria for stainless steel impact testing? With respect to specimen geometry, UG-84 (4) (a) provides scaling methods for absorbed .This document provides guidelines for Charpy impact tests on welded vessels and vessel components. It outlines the general scope of materials that require impact testing, acceptable test procedures and apparatus, minimum test . Notable updates have been applied to Figures UG-84.1 and UG-84.1M. These revisions include the incorporation of test requirements for materials with a minimum specified yield of 80 Ksi and 550.ug-84: charpy impact tests This test is performed to check the brittleness (of a normally ductile material) tendency of material at low temperatures. They are performed for the weldment (Weld & HAZ) and for the parent material.

UG-84.1. Charpy impact test requirements for carbon steel and low alloy steel samples (listed in UCS-23) having a tensile stress lower than 655 MPa.UG-84.1 Charpy V-Notch Impact Test Requirements for Full Size Specimens for Carbon and Low Alloy Steels, Having a Specified Minimum Tensile Strength of Less Than 95 ksi, Listed in . UG-84 Charpy Impact Test. UG-85 Heat treatment. UG-93 Inspection of materials. UHT-81 Heat treatment verifica tion tests. UHT-82 W elding. UW-3 Welded joint category. Citations (0) References (16) RE: UHA-51, UG-84 - Impact testing for stainless steel Fizza453 (Mechanical) 25 Jan 14 03:47 Figure 3.6 is for the carbon and low alloy steels with minimum specified tensile strength greater than or equal to 655 MPa (95 ksi), please see 3.11.2.1(b)(2).

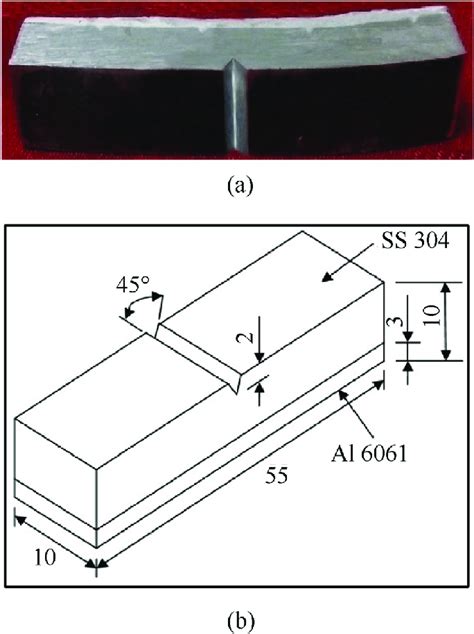

Charpy Impact Test, Drop Weight Test]. Module 2 reviews the paragraph UG-84 CHARPY IMPACT TESTS of ASME Section VIII, Division 1 and its various subparagraphs with detailed examples to provide a deeper understanding of the code rules. Module 3 covers some of the important rules of Part UCS and UHA The impact test specimen width is only 3.3mm (66% of the material thickness) and Table UG-84.2 specifies a temperature reduction of 19°C. The actual reduction in test temperature below the MDMT ( in our case -50°C) for this situation is the difference between these two temperatures, namely:

My current weld procedures cover both weld zone impact testing down to -50F and PWHT which I am required to do in this case because of thickness It almost appears that I need to use UCS-67(a)to exempt myself out of UG-84(h) and subsequently UG-84(i) in order to not do the production tests Title : Test - Impact Test . 1. 충격시험 (Impact Test) . +UG 84 : 충격시험 온도는 최저 사용 설계온도에 따른다. 2. 규격 ASTM A20에서 규정하는 시험온도가 최저사용 설계온도보다 저온인 경우는 +S5로 표시하고 고온인 경우는 +UG 84로 .You need to follow the following clauses to make exemption assessment for ASME impact test requirement: UG-20(f) →→→UCS-66(a) →→→ UCS-66(b) →→→UCS-68(c) First you have to keep your pressure vessel design data available and then refer to UG-20 (f). If you are exempted from this clause, you do not need proceed further.UG-84.1 requires that the impact test results must average 30 ft-lbs. or more to qualify for a thickness of 3 inches or more. Issued 2016-04-08 AB-511 Edition 2, Revision 1 Page 9 of 14 The Impact Testing Enigma 5.0 FABRICATION 5.1 UCS-67(a) This paragraph stipulates that welds made with filler metal shall be deposited using welding procedures .

(Fig UG 84.1). The following two programs compute the impact requirements of Fig UCS 66 and Fig UCS 66.1. . FIG UCS-66.1 Reduction in Min Design Metal Temp Without Impact Testing Enter either ratio defined below and click the calculate button. The impact test temperature can be made warmer by the calculated temperature difference. UG-84(i) Subject Description: Production Impact Test Plates for Repair Welding. Date Issued: 01/03/2020. Record Number: 19-1893. Interpretation Number : BPV VIII-1-20-01. . is the repair welding procedure also required to be .UG-84.1M Charpy V‐Notch Impact Test Requirements for Full-Size Specimens for Carbon and Low Alloy Steels, Having a Specified Minimum Tensile Strength of Less Than 655 MPa, Listed in Table UCS-23. Bạn đang xem bản rút gọn của tài liệu. Xem và tải ngay bản đầy đủ của tài liệu tại đây (20.89 MB, 796 trang )

Per UG 84, test at the MDMT or colder. See UG 84(b) RE: MDMT and impact test temperature puigi (Mechanical) 10 Nov 11 10:42. . It means, for SA516Gr60N, it'll be able to perform impact test required by UCS66 at -30°F (-34°C) because yield strength for SA516Gr60N is lower than 40KSI (32KSI). Is my understanding correct ? Thank for your . 5.5 UG-84(f)(2) Impact Testing of Welds . All test plates (PQR and Production, when not exempted) shall be subjected to heat treatment, including cooling rates and aggregate time(s) at temperature(s) as established by the Manufacturer for use in actual manufacture. This paragraph can have significant consequences when an exemption under the . Impact Test 요건. Impact Test는 기본적으로 아래 내용을 알고 계셔야 합니다. 1. UG-20(f) : Impact Test 면제 조건. 2. UG-84 : Impact Test 절차, 합부기준 및 특수조건 등. 3. UCS-66 : 탄소강 및 저합금강에 대한 MDMT 및 충격시험. 4. UCS-67 : 탄소강 및 저합금강에 대한 용접절차의 충격 .

UG-84.1 requires that the impact test results must average 30 ft-lbs. or more to qualify for a thickness of 3 inches or more. Issued 2016-04-08 AB-511 Edition 2, Revision 1 Page 9 of 14 The Impact Testing Enigma 5.0 FABRICATION 5.1 .Impact test: The impact test according to UG-84 is not mandatory for materials subjected to pressure that meet the following conditions: The material will be P-Nº1, Gr. Nº 1 or 2 and the thickness will be defined in UCS-66 (a) and the . As per UG-84(g) "Each set of weld metal impact specimens shall be taken across the weld with the notch in the weld metal. Each specimen shall be oriented so that the notch is normal to the surface of the material and one face of the specimen shall be within 1/16 in. (1.5 mm) of the surface of the The standard (10 mm x 10 mm) specimens, when obtainable, shall be used for nominal thickness of 7/16 in. or greater. When the specimen width along the notch is at least 8 mm, the impact test .

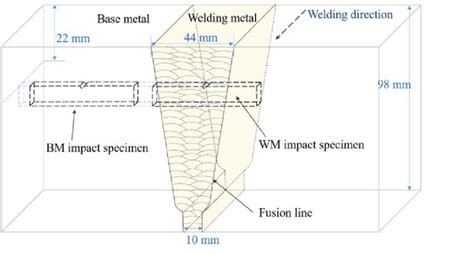

mts axial torsion test 858

Download scientific diagram | Impact testing of welds UG-84 (f.2). from publication: Teaching how to determine the Charpy impact according to the general requirements defined in part-UG of the . On the new edition of the code ASME VIII Div.I Ed.2013, new locations of impact test has been added (Table UG-84.6) for the heat affected zone; for example: For thickness >19mm two sets of impact tests shall be removed from a depth of between 1/4t and 1/2t from the weld surface, and a second specimen set shall be removed from a depth of between . Location of notch as per UG-84(g) for impact test specimen Location of notch as per UG-84(g) for impact test specimen Genetix (Petroleum) (OP) 18 Aug 16 08:36. Dear respected experts of this forum. I would like to get some insight regarding UG-84(g) of ASME Section VIII Division 1.

Impact Test 요건. Impact Test는 기본적으로 아래 내용을 알고 계셔야 합니다. 1. UG-20(f) : Impact Test 면제 조건. 2. UG-84 : Impact Test 절차, 합부기준 및 특수조건 등. 3. UCS-66 : 탄소강 및 저합금강에 대한 MDMT 및 충격시험. 4. UCS-67 : 탄소강 및 저합금강에 대한 용접절차의 충격 .each weld process has been tested as per UG-84(h)(5), the vessel impact test plate, would satisfy UG-84(i)(1). Interpretation VIII-1-21-12 supports this approach. A test plate weldment completed with the first production longitudinal seam that includes two or three

Fig. UCS-66 Impact test exemption curves [Ref: ASME Sec. VIII Div.1] ASME Sec. VIII Div.1: UCS-66(a) Unless exempted in UG-20(f), Fig. UCS-66 shall be used to establish impact testing exemptions for steel listed in part UCS. Impact testing is checked for the combination of minimum design metal temperature and governing thickness of the part. Under Vessel (Production) Impact Tests Plates (UG-84 (i) of Section VIII Div 1), there is the following statement about the materials used to make the test pla . Don't worry about production testing the Cat D's. See UG 84 (i)(3) Red Flag This Post. Under the provisions of UG-84(i)(3)(a), is one production impact test plate per weld procedure all that is required for a single vessel regardless of the length of welding involved and variations in wall thickness? Reply 1: Yes. Question 2: UG-84(i)(3)(b) requires that for several vessels or parts of vessels welded within any 3 month period at . Please help me understand some points regarding Impact testing required energy as per ASME BPVC. First question is what is meant by minimum specified yield strength in Figure UG-84.1? Is it the value specified by the code in II-D or is .

production welding impact testing

heat impact test specimen

heat impact test samples

Reload page 2M Followers, 0 Following, 81 Posts - See Instagram photos and videos from 𝐘𝐈𝐍𝐘𝐋𝐄𝐎𝐍 (@Yinyleonofficial)

ug-84 impact test|heat impact test specimen